India’s tech industry is transforming remarkably, with the semiconductor sector playing a pivotal role. These tiny chips, which power everything from smartphones to advanced AI systems, are critical to modern electronics. While India has long been a consumer of semiconductors, the country is now making significant strides toward becoming a key player in their production. This is not just a matter of national pride, but also a strategic necessity as global supply chains increasingly look to diversify.

Meeting the Rising Demand in India’s Expanding Digital Economy

India’s demand for semiconductors is expanding rapidly, driven by the rise of industries such as telecommunications, consumer electronics, electric vehicles, and more. The need for high-performance, energy-efficient chips is soaring as technologies like 5G, artificial intelligence (AI), and the Internet of Things (IoT) become more integrated into everyday life. Traditionally, India has relied heavily on imports to meet its semiconductor needs, but the recent global chip shortages have underscored the risks of such dependence.

Globally, the semiconductor market is expected to surpass $500 billion, with India’s share projected to exceed $100 billion by 2030. This booming demand presents India with a unique opportunity to not only consume semiconductors but also produce them.

Strategic Investments and Policy Support Paving the Way for a Semiconductor Hub

Recognizing the strategic importance of semiconductors, the Indian government has introduced several initiatives to strengthen the industry. The Indian Semiconductor Mission (ISM), as part of the larger Production Linked Incentive (PLI) Scheme, is central to this effort. By offering financial incentives, infrastructure support, and subsidies, the government is laying the foundation for a robust domestic semiconductor ecosystem.

These policies have already attracted major global players like Intel and Micron to set up design centers and explore manufacturing opportunities in India. This local production push is not only crucial to meet domestic demand but also aligns with India’s ambitions to emerge as a global semiconductor hub.

Overcoming the Challenges of Establishing India’s First Semiconductor Fabs

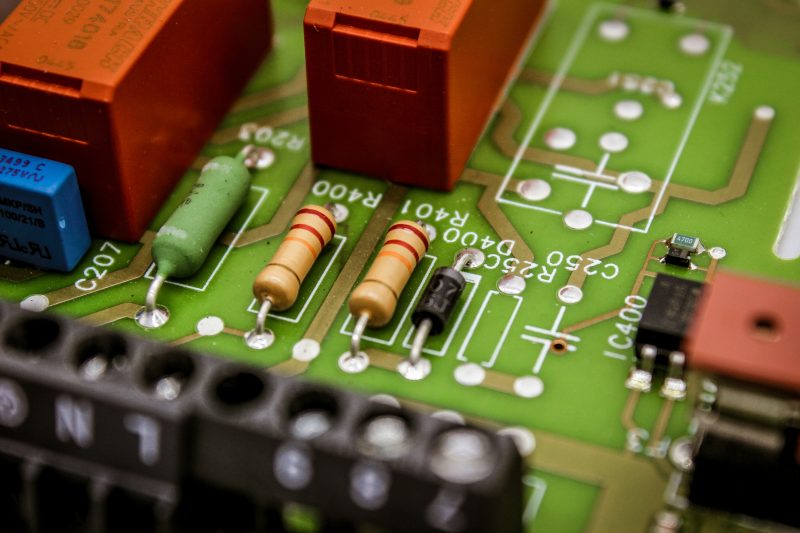

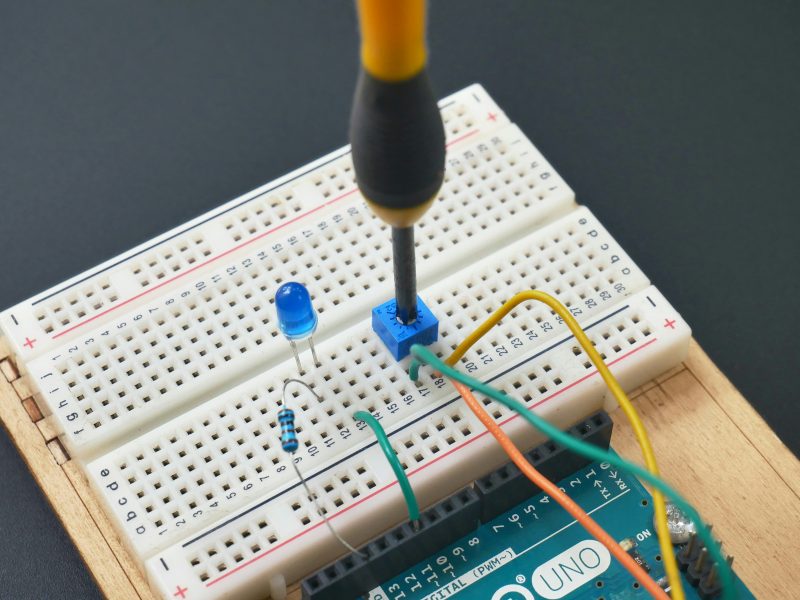

While India has made great progress in semiconductor design, establishing large-scale fabrication plants (fabs) has proven more difficult. Semiconductor manufacturing requires significant capital investment and advanced infrastructure, including consistent power and water supply. However, the approval of three semiconductor fabs, valued at $11 billion, demonstrates India’s commitment to building this vital capacity.

These fabs, which will produce chips with nodes ranging from 28nm to 110nm, are a crucial step in reducing India’s dependence on imports. Furthermore, investments in assembly, testing, and packaging (ATMP) facilities are strengthening the overall semiconductor ecosystem within the country.

How Semiconductors Are Driving Innovation Across Key Industries

The rise of the semiconductor industry is having a profound impact on India’s broader tech ecosystem. Innovations in chip manufacturing are fueling advances in sectors like telecommunications, automotive, and consumer electronics. For instance, the move toward smaller, more efficient process nodes—such as 45nm chips—has significantly improved performance in smartphones and electric vehicles while reducing energy consumption.

India is also emerging as a global hub for semiconductor design. With companies like Qualcomm and AMD establishing Global Capability Centers (GCCs) in India, the country is becoming a focal point for semiconductor research and development. This growing expertise is creating thousands of high-quality jobs and nurturing a new generation of engineers skilled in cutting-edge technologies.

Positioning India as a Key Player in the Global Semiconductor Supply Chain

The global chip shortage and geopolitical tensions have emphasized the need for countries to diversify their semiconductor supply chains. India, with its growing technical capabilities and favorable policy environment, is well-positioned to become a reliable partner in this global shift.

Partnerships like the one between Tata Electronics and Tokyo Electron are helping to solidify India’s role in the global semiconductor market. These collaborations are not only boosting domestic manufacturing capacity but also ensuring that India becomes an integral part of the worldwide semiconductor ecosystem.

Addressing the Roadblocks on India’s Semiconductor Path

Despite the positive momentum, there are still significant challenges that India must overcome. Establishing semiconductor fabs requires immense capital, and private investors have been cautious due to the high risks and competition from established players in Taiwan and South Korea. Additionally, India needs to focus on research and development to remain competitive in this fast-paced industry.

Building a sustainable semiconductor ecosystem will also require improvements in infrastructure, particularly in ensuring reliable access to power and water. Addressing the skills gap through advanced training for engineers is essential for India to build a future-ready workforce. Strategic partnerships and sustained investments in talent and R&D will be critical to overcoming these hurdles.

By Anamika Singh – CEO, StraCon Business Services and Rohit Kumar Singh